Research Laboratory “Polymer composite materials in shipbuilding”

Purpose of activity:

– to establish the basic patterns of influence of energy fields and the nature of fillers on the mechanism of structure formation of polymeric composites and to give recommendations on creation of functional coverings on their basis for protection of the technological equipment against corrosion and wear;

– searching, testing of working hypotheses about the connections of the main physical-mechanical and thermophysical properties of composites and development of software for their testing by numerical methods.

The result of the development should be the ability to predict one or several properties of composites using an acceptable accuracy for practice based on information about others that have been well studied.

The team:

1. Doctor of technical sciences, professor, Academician of the Academy of Engineering Sciences of Ukraine, Academician of the Handling Academy of Sciences of Ukraine, Honored Worker of Science and Technology of Ukraine, Laureate of the State Prize of Ukraine, Head of the Department of Transport Technologies and Mechanical Engineering Buketov Andrey Viktorovich – Head of Laboratory.

2. Aleksenko Viktor Leonidovych, senior lecturer of the Department of Transport Technologies and Mechanical Engineering, head of the laboratory.

3. Doctor of technical sciences, professor of the Department of Transport Technologies and Mechanical Engineering of KSMA Sapronov O.O.

4. Doctor of technical sciences, professor, professor of the Department of Transport Technologies and Mechanical Engineering of KSMA Sharko O.V.

5. Doctor of technical sciences, professor, professor of the Department of Transport Technologies and Mechanical Engineering of KSMA Klevtsov K.M.

6. Doctor of technical sciences, professor, rofessor of the Department of Computer-Integrated Technologies of Ternopil Ivan Pul’uj National Technical University Stukhlyak P.D.

7. Candidate of technical sciences, Associate Professor, doctoral student, Associate Professor of the Department of Transport Technologies and Mechanical Engineering of KSMA Brailo M.V.

8. Candidate of technical sciences, doctoral student at the Department of Transport Technologies and Mechanical Engineering Buketova N.M.

9. Candidate of technical sciences, Associate Professor, Associate Professor of the Department of Transport Technologies and Mechanical Engineering of KSMA Akimov O.V.

10. Doctor of Philosophy, Associate Professor of the Department of Navigation Yakushchenko S.V.

11. Associate Professor of the Department of Transport Technologies and Mechanical Engineering Smetankin S.O.

12. Candidate of technical sciences, Associate Professor, researcher of the scientific group at the Department of Transport Technologies and Mechanical Engineering Bogdan Y.O.

13. Candidate of technical sciences, researcher of the scientific group at the Department of Transport Technologies and Mechanical Engineering Leshchenko O.V.

14. Candidate of technical sciences, researcher of the scientific group at the Department of Transport Technologies and Mechanical Engineering Nigalatiy V.D.

15. Candidate of technical sciences, Associate Professor, head of the Maritime College of KSMA V.M. Gusev.

16. Doctor of Philosophy, Senior lecturer of the Department of Transport Technologies and Mechanical Engineering Kulinich A.G.

17. Assistant at the Department of Transport Technologies and Mechanical Engineering Bogdan A.P.

18. Doctor of Philosophy, researcher of the scientific group at the Department of Transport Technologies and Mechanical Engineering Kulinich V.G.

19. Doctor of Philosophy, researcher of the scientific group at the Department of Transport Technologies and Mechanical Engineering Zhytnyk D.V.

20. Doctor of Philosophy, researcher of the scientific group at the Department of Transport Technologies and Mechanical Engineering Sapronova A.V.

21. Doctor of Philosophy, researcher of the scientific group at the Department of Transport Technologies and Mechanical Engineering Chernyavska T.V.

22. Graduate student Yurenin K.Y.

23. Graduate student Sotsenko V.V.

24. Graduate student Babiy K.A.

Scientific and practical direction of activity:

development of new technologies and materials with increased performance characteristics for the protection of ship hulls;

study of the influence of physical fields on the properties of composite materials;

nanocomposites and nanotechnologies in modern industry;

use of information technologies in modeling complex systems and forecasting their properties.

Objectives of the study:

to develop methodological approaches of the study of the influence of energy fields (magnetic, ultrasonic, ultraviolet radiation) on the properties of polymer composites;

to establish the mechanisms of interphase interaction of dispersed and fibrous fillers with a polymeric binder at the nano-, micro- and macro-levels;

to investigate the influence of the nature of the filler on the characteristics of the structure of the outer surface layers at the “polymer – filler” phase (density, degree of crosslinking, geometric dimensions);

to give recommendations on creation on the basis of the developed composites of protective coverings of various functional purpose and to carry out their introduction in the industry.

Today the laboratory is equipped with modern technological equipment for structure research: EPR and IR spectroscopy, Tovarov device, Soxhlet device; physical and mechanical properties: universal testing machine, installation for the study of materials bending; rheological (rotary viscometer), thermophysical (heat resistance, DTA, DTС, coefficient of thermal expansion, dielectric characteristics) properties and wear resistance (friction machine). Additionally, there is a possibility to process the compositions with ultrasound (device UZDN-1500), magnetic fields and ultraviolet radiation.

Innovation idea:

The project idea is to study the influence of physical nature of fillers, magnetic processing, ultrasonic and ultraviolet irradiation of compositions at the preliminary stage of forming materials on the physical and mechanical, thermophysical properties, corrosion resistance and wear resistance of protective coatings. In order to determine and optimize the composition of coatings and modes of magnetic processing, ultrasonic and ultraviolet irradiation, as well as the predicted regulation of the structure and properties of heterogeneous materials, it is planned to develop and substantiate the interaction control mechanism at the phase boundary “base – polymer composite coating”.

Investigation of the structure of epoxy composites using EPR-spectral analysis (doctor of technical sciences, professor Sapronov O.O.

Studies of the structure of epoxy composites using IR spectral analysis are performed by graduate students under the guidance of senior lecturer V.L. Alekseenko

Ultrasonic processing of compositions (doctor of technical sciences. A.V. Buketov, candidate of technical sciences, doctoral student Brailo M.V.)

Ultrasonic processing of compositions with nanoparticles (graduate student Sotsenko V.V.)

The study of the thermal coefficient of linear expansion of composite materials is performed by doctor of philosophy Smetankin S.O. on an automated installation, which is developed in the laboratory of polymer and composite materials in shipbuilding

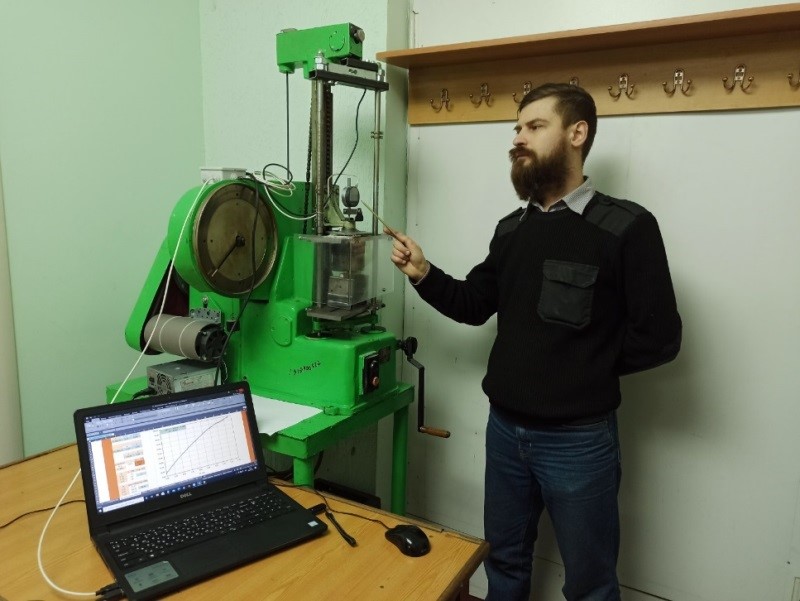

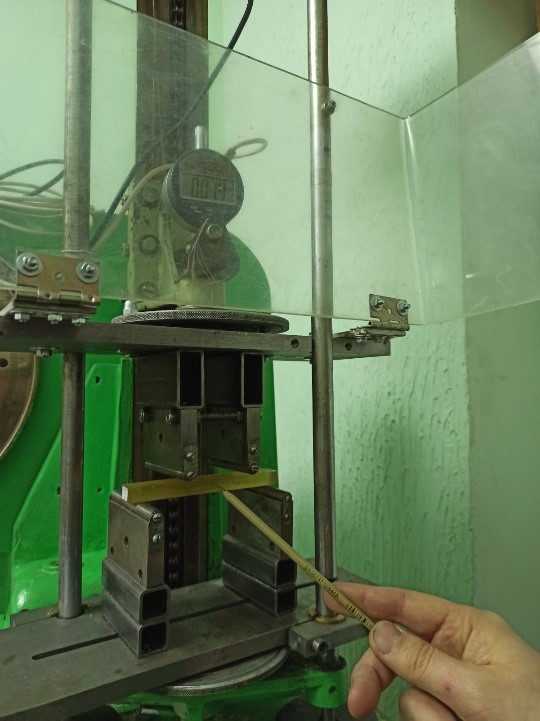

The study of tension breakings and elastic modulus in bending is performed by graduate student Yurenin K.Y. on an automated installation, which is modernized in the laboratory of polymer and composite materials in shipbuilding

Viscometer ‘Brukfield’ (Germany)

Measurement of the thickness of the applied anticorrosive coating, which was developed in the laboratory, in industrial conditions is performed by doctor of philosophy Yakushchenko S.V.

The product

On the basis of the conducted researches and received results, new composite materials and coverings on their basis with forecasted operational characteristics for protection of the technological equipment against corrosion and wear are created.

Adding a layer of polymer coating on the ship hull (a) and on the hydraulic system valve (b)

Analysis of corrosion destruction of deck mechanisms of the ship “Oles Honchar”

New materials, methods and ways to increase corrosion resistance and wear resistance of protective coatings have been developed, which have a priority character and are protected by patents of Ukraine. Multilayer coatings based on epoxy composite materials provide high performance indicators and are suitable for protecting the surfaces of structural elements of mechanisms from the effects of aggressive environments and hydroabrasives.

Implementation of the results of development is possible at all shipyards of the Kherson area, which are engaged in questions of testing of structure elements, aspects of increasing the anticorrosive characteristics and wear resistance of technological equipment. In addition, it is possible to implement the results of work in the chemical, food, oil refining, radar and mechanical engineering industries in order to increase the work resource of equipment.

Patents of Ukraine for utility models obtained by the laboratory staff

Problem and opportunity

Today, not enough attention is paid to the development of new epoxy composites in the modification of both ingredients and compositions, by external energy fields in the initial stages of their formation. This has opened up fundamentally new opportunities in the creation of new protective coatings with increased performance characteristics. Therefore, the study of crosslinking of epoxy composites under the influence of magnetic field, ultrasonic and ultraviolet radiation to increase the performance characteristics of protective coatings is an urgent task of modern materials science.

The advantage of development over foreign and domestic analogs is the review of the main factors of aggressive environments where technological equipment is used, and also creation of materials that in a complex have high indicators of physical and mechanical, thermophysical properties, corrosion durability and wear resistance. The technological process of forming polymer composite materials will correspond to the state of similar technologies developed by scientific research institutes in Belarus, the Baltics, Russia, Germany, the USA and Japan.

All ingredients of composite materials and protective coatings based on them (epoxy, plasticizers, fillers) are contained in Ukraine. Thus, such disperse fillers, as red and brown sludge, gas soot, ferrite are wastes of the industrial enterprises that allows to make the assumptions about economic efficiency of introduction of new materials.

In addition, the staff of the Kherson State Maritime Academy has developed technological equipment, which is currently available (installation for magnetic, ultrasonic processing and ultraviolet emitter), for processing the oligomeric compositions with external energy fields.

Proposals for implementation

Implementation of coatings at enterprises will provide: increasing the corrosion resistance of equipment by 2.5… 2.7 times, increasing the resistance to wear by 2.0… 2.2 times, increasing the service life by 3.0 … 3.5 times.

Implementation of the results of development is possible at all shipyards of the Kherson area, which are engaged in questions of testing of structure elements, aspects of increasing the anticorrosive characteristics and wear resistance of technological equipment. In addition, it is possible to implement the results of work in the chemical, food, oil refining, radar and mechanical engineering industries in order to increase the work resource of equipment.